Best Stick Welding Gloves: Your Ultimate Guide to Hand Protection

This article is your one-stop guide to understanding and choosing the best stick welding gloves. If you're a professional welder or a DIY enthusiast, you know that safety is paramount. This article explains why choosing the right welding glove is critical, not just for protection but also for improving your welding performance. We'll cover everything from materials and design to specific recommendations, making it worth your time to read and ensure you're making the best investment for your hands and your craft.

Why Are the Right Welding Gloves Crucial for Stick Welding?

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a welding process that generates intense heat, sparks, and ultraviolet radiation. Using the right welding glove is absolutely essential for several reasons. First and foremost is safety. Without proper protection, welders risk severe burns, cuts, and long-term skin damage.

Secondly, the right welding gloves can make a significant difference in the quality of your work. A glove that fits well and provides adequate dexterity allows for better control of the electrode, leading to more precise and consistent welds. Conversely, ill-fitting or overly bulky gloves can hinder movement and reduce accuracy. Because welding involves high heat and complex movements, you must consider protection.

What Materials Are Best for Stick Welding Gloves?

Welding gloves are made from a variety of materials, each with its own strengths and weaknesses. For stick welding, which produces a lot of heat and sparks, the most common and effective material is leather. Within the leather category, there are several options:

-

Cowhide: Cowhide is a popular choice due to its excellent durability, heat resistance, and abrasion resistance. It's also relatively affordable, making it a good all-around option for stick welding gloves.

-

Elkskin: Elkskin is known for its superior heat resistance and flexibility, even after repeated exposure to high temperatures.

-

Pigskin: Pigskin gloves offer good abrasion resistance and breathability, but may not provide as much heat resistance as cowhide or elkskin.

-

Goatskin: Goatskin gloves are typically thinner and offer greater dexterity, making them better suited for TIG welding than stick welding.

Some gloves also incorporate materials like Kevlar stitching for added strength and durability. Kevlar is a synthetic fiber known for its high tensile strength and heat resistance.

How Does the Design of a Welding Glove Impact Performance?

The design of a welding glove goes beyond just aesthetics; it directly influences how well you can perform your welding tasks. Stick welding requires a good grip and control over the electrode holder.

-

Cuff Length: Stick welding gloves typically have a longer cuff (at least 4 inches) to protect the forearm from sparks and spatter.

-

Reinforcements: Many gloves feature reinforced palms and thumbs, areas that experience the most wear and tear during welding. This added layer of material enhances durability and protection. For example, 14-inch Thick Palm Welding Protective Gloves provide extra material in the palm.

-

Lining: A comfortable lining, often made of cotton or a flame-resistant material, adds comfort and helps absorb sweat.

What Are the Key Features to Look for in Stick Welding Gloves?

When shopping for welding gloves, several key features should be at the top of your checklist. These ensure that the gloves meet the demands of stick welding and provide adequate protection.

-

Heat Resistance: This is arguably the most crucial feature. Stick welding generates significant heat, so your gloves must be able to withstand high temperatures without degrading or transferring heat to your hands. Gloves provide protection by being made with heavy leather.

-

Durability: Welding is a tough job, and your gloves need to be able to withstand constant abrasion, sparks, and spatter. Look for gloves made from durable materials like cowhide or elkskin with reinforced stitching.

-

Dexterity: While protection is paramount, you also need to be able to manipulate the electrode and welding tools effectively. The glove shouldn't be so bulky that it restricts your movement.

-

Cut Resitance: Some gloves offer cut resistance, providing protection against sharp edges and handling of materials.

How Do I Choose the Right Size and Fit for Welding Gloves?

Choosing the right size and fit is critical for both comfort and performance. Gloves that are too small will restrict movement and blood flow, while gloves that are too large will be clumsy and make it difficult to grip the electrode holder.

Most welding glove manufacturers provide sizing charts based on hand circumference and length. Measure your hand carefully and compare it to the chart to find the best fit. It's also a good idea to try on gloves if possible, as sizing can vary slightly between brands. Remember, a comfortable fit is essential for long welding sessions. Wearing gloves that are too tight may cut off circulation.

Are There Different Welding Gloves for Different Types of Welding?

Yes, there are. While there's some overlap, different welding processes have different requirements. Stick welding, for example, produces more sparks and spatter than TIG welding, requiring more robust hand protection.

-

Stick Welding Gloves: As discussed, these gloves prioritize heat and abrasion resistance.

-

MIG Welding Gloves: MIG welding also generates significant heat, but MIG gloves may offer slightly more dexterity than stick gloves because the welding process can be less demanding in terms of electrode manipulation.

-

TIG Welding Gloves: TIG welding requires the most dexterity, as it involves precise control of a small electrode and often the addition of filler metal. TIG gloves are typically thinner and made from materials like goatskin or kidskin to maximize feel and control. Tig gloves provide excellent flexibility.

How do Certifications Impact My Welding Glove Choice?

Certifications, such as those from CE and ANSI, are critical indicators of a welding glove's quality and safety compliance. These certifications mean that the gloves have been tested and meet specific standards for heat and flame resistance, puncture resistance, and other safety criteria.

-

CE Certification: This marking indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA).

-

ANSI Certification: The American National Standards Institute (ANSI) sets standards for a wide range of products, including welding gloves. Look for ANSI/ISEA 105 ratings, which cover cut resistance, puncture resistance, and abrasion resistance.

Always look for gloves that meet the relevant safety standards for your region and the type of welding you'll be performing. This ensures you're getting the best protection possible.

What Are Some Common Mistakes to Avoid When Buying Welding Gloves?

One of the biggest mistakes is prioritizing price over quality. While it's tempting to save money, cheap gloves often compromise on protection and durability, potentially leading to injuries and the need for frequent replacements.

Another mistake is choosing the wrong type of glove for the welding process. Using TIG gloves for stick welding, for example, will provide insufficient protection from the intense heat and sparks. Ignoring fit is also a common error. Gloves that don't fit properly will hinder your performance and can even be dangerous.

How Can I Maximize the Lifespan of My Welding Gloves?

Proper care and maintenance can significantly extend the life of your welding gloves. Here are some tips:

-

Keep them clean: Regularly brush off dirt, debris, and weld spatter. For heavier cleaning, use a leather cleaner and conditioner.

-

Store them properly: Store your gloves in a dry, well-ventilated area away from direct sunlight and extreme temperatures.

-

Inspect them regularly: Before each use, check your gloves for signs of wear and tear, such as holes, tears, or thinning material. Replace gloves that are damaged.

-

Rotate pairs: If you weld for long periods, consider rotating between multiple pairs of gloves to reduce wear on any single pair.

Where Can I Find High-Quality Welding Gloves for My Business?

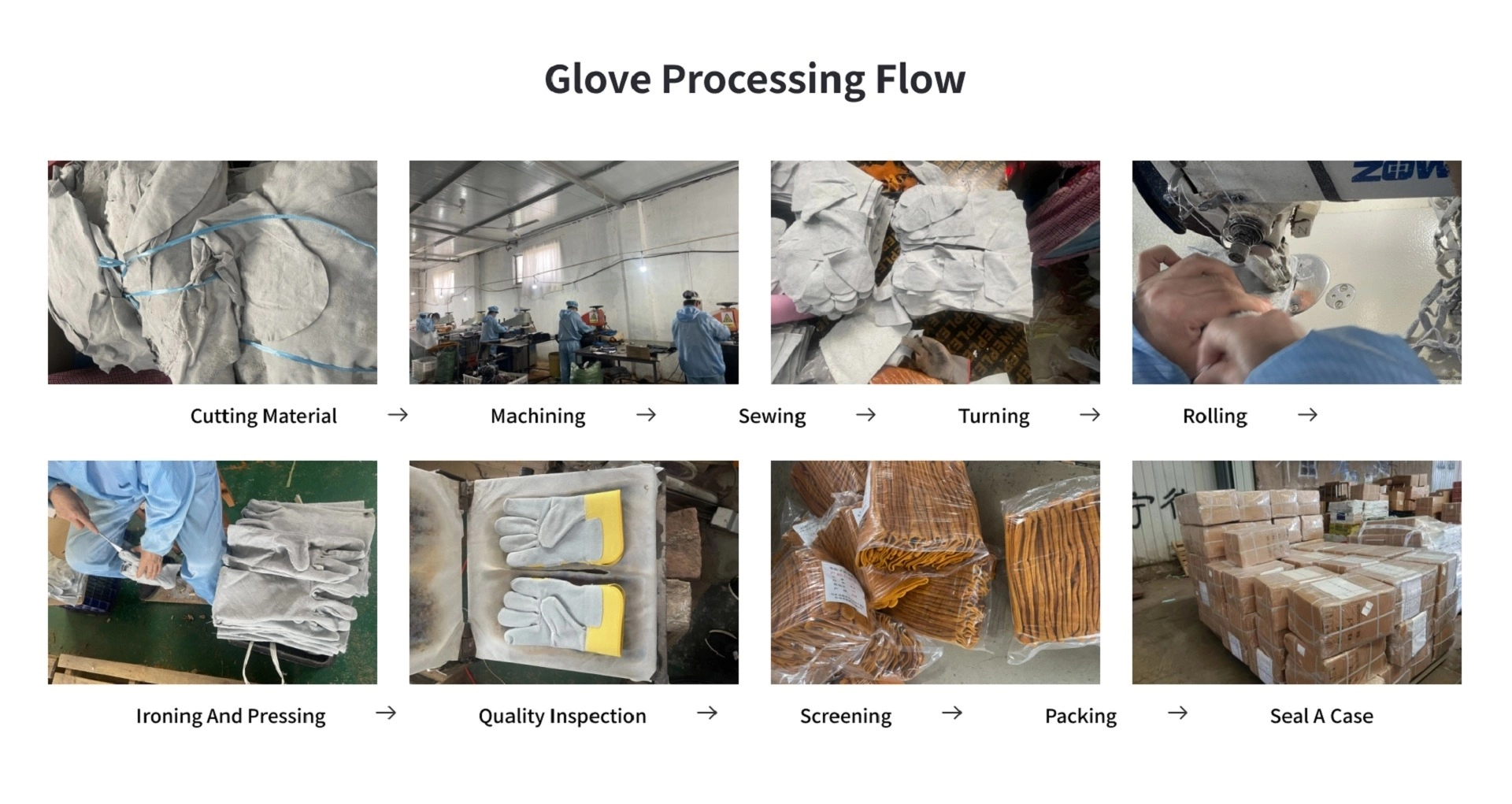

Finding a reliable supplier is key, especially for businesses that need a consistent supply of high-quality welding gloves. As a factory specializing in protective gloves and apparel, DTlabor offers a wide range of welding gloves designed for various applications, including stick welding. We have multiple production lines and export to major markets like the USA, North America, Europe, and Australia.

We understand the needs of safety equipment distributors, welding supply companies, and other businesses that require durable, compliant, and competitively priced protective gloves. We are proud to be a Chinese company, serving customers like Mark Thompson. He values the ability to purchase cost effective gloves. He can then sell these to make a profit.

Our gloves are made from high-quality materials, including various types of leather and treated fabrics, and are designed to meet relevant safety standards. We also offer customization options to meet specific customer requirements. Another great pair of gloves from DTlabor is the AB Grade 14 Inch Single Layer + Edge Strip + Fireproof Line.

Another example of a great product is Long Style Palm leather arm canvas welding work gloves.

Quotes:

"The difference between a good welder and a great welder is often the attention to detail, and that includes choosing the right protective gear." - Allen, DT Labor.

"Safety isn't expensive, it's priceless. Investing in quality welding gloves is an investment in your well-being and your craft." - A Veteran Welder

Statistics:

- According to the U.S. Bureau of Labor Statistics, welders, cutters, solderers, and brazers experienced over 14,000 hand injuries in 2020.

- A study by the National Institute for Occupational Safety and Health (NIOSH) found that wearing appropriate gloves can reduce the risk of hand injuries by up to 60%.

Table: Comparison of Welding Glove Materials

| Material | Heat Resistance | Durability | Dexterity | Cost | Best For |

|---|---|---|---|---|---|

| Cowhide | Excellent | Excellent | Good | Moderate | Stick, MIG |

| Elkskin | Superior | Very Good | Very Good | High | Stick, MIG |

| Pigskin | Good | Very Good | Good | Moderate | MIG, some Stick |

| Goatskin | Good | Good | Excellent | Moderate to High | TIG |

| Combination (e.g., cowhide with Kevlar) | Varies | Very Good | Varies | Moderate to high | Stick, MIG |

Summary of Important Points:

- Welding gloves are essential for safety and performance in stick welding.

- Choose gloves made from durable, heat-resistant materials like cowhide or elkskin.

- Ensure the gloves fit properly and provide adequate dexterity.

- Look for gloves that meet relevant safety certifications (CE, ANSI).

- Proper care and maintenance will extend the life of your gloves.

- Consider partnering with a reliable supplier like DTlabor for high-quality welding gloves and apparel. Many welders need to make sure they are protected.

- Good welding gloves can make a big difference in your work.

- Leather work gloves are essential for stick welding.